Smart Factories in Detroit: How Azure Powers the Next Industrial Revolution

Introduction:

Detroit has always been synonymous with innovation in manufacturing. From the birth of the assembly line to the rise of connected vehicles, the city has defined industrial progress for over a century. Now, as we enter the era of Industry 4.0, Detroit manufacturers face a new challenge: how to modernize factories to compete globally while controlling costs, maintaining quality, and meeting sustainability goals.

Smart factories powered by cloud computing, IoT, AI, and data-driven decision-making are the cornerstone of Industry 4.0. But without the right digital backbone, these initiatives stall. That’s where Microsoft Azure becomes a game-changer, offering Detroit manufacturers the tools to unlock new efficiencies, reduce downtime, and transform how factories operate.

The Manufacturing Pain Points in Detroit

Before diving into solutions, let’s look at the realities Detroit manufacturers face today:

- Legacy Systems Still Dominate: Many factories rely on outdated ERP or MES systems that don’t integrate with modern IoT or analytics platforms.

- Data Is Siloed: Machine data, supplier data, and customer demand data often live in separate systems, making it hard to get a “single source of truth.”

- Unplanned Downtime: Equipment failures can cost manufacturers millions in lost productivity.

- Global Competition: Detroit’s automakers and parts suppliers must compete with leaner operations in Asia and Europe.

- Compliance and Security: Manufacturing data is sensitive, and connected devices expand the attack surface for cyber threats.

These challenges point to one solution: a secure, scalable, cloud platform built for manufacturing.

Why Azure for Industry 4.0?

Azure is more than just cloud storage—it’s a complete digital foundation. For manufacturers, Azure enables:

- IoT at Scale: Azure IoT Hub and Digital Twins let you connect thousands of machines, sensors, and systems securely.

- Advanced Analytics: With Azure Synapse Analytics and Power BI, manufacturers can turn machine-level data into actionable insights.

- AI & Machine Learning: Azure Machine Learning helps predict failures, optimize supply chains, and even improve product quality.

- Hybrid Flexibility: With Azure Stack, Detroit factories can run workloads both on-premises and in the cloud ideal for plants with regulatory or latency requirements.

- Built-in Security & Compliance: Azure Defender and Sentinel provide enterprise-grade security, critical for manufacturing IP and compliance.

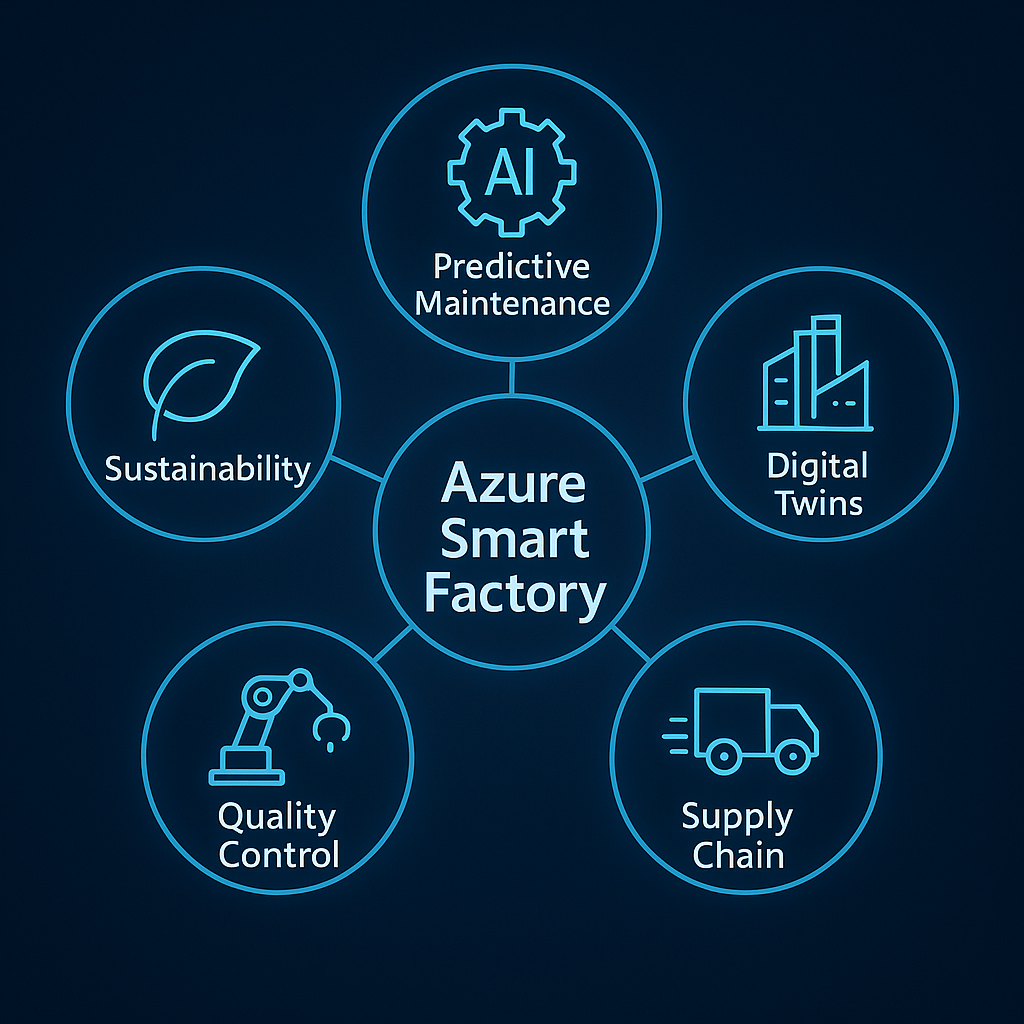

Smart Factory Use Cases with Azure

1. Predictive Maintenance

Instead of reacting to breakdowns, Detroit manufacturers can use Azure Machine Learning models trained on IoT sensor data to predict when equipment will fail. This helps reduce costly downtime and extend machine life.

- Example: A Tier-1 automotive supplier uses Azure IoT Edge sensors on stamping machines to detect vibration anomalies, predicting failures before they halt production.

2. Digital Twins for Factories

Azure Digital Twins creates virtual replicas of machines, production lines, or entire plants. This helps engineers simulate scenarios and test optimizations without touching the physical equipment.

- Example: Automakers can model a paint shop digitally, experimenting with airflow adjustments to reduce paint waste and energy usage.

3. Supply Chain Visibility

Azure Synapse Analytics combined with Azure Data Lake provides real-time insights across suppliers, logistics, and customer demand. This reduces bottlenecks and enables agile decision-making.

- Example: A Detroit OEM uses Azure to connect supplier data, predicting part shortages early and rerouting logistics before assembly lines stop.

4. Smart Quality Control

With Azure AI Vision, manufacturers can integrate AI-driven quality checks directly into production lines. Defects can be detected earlier, reducing rework and scrap.

- Example: An automotive plant integrates Azure Vision to inspect weld quality on frames, ensuring structural integrity before vehicles move to final assembly.

5. Energy Optimization & Sustainability

Azure IoT and AI can track energy usage across facilities and recommend optimizations. This is increasingly critical as Detroit manufacturers set sustainability goals.

- Example: A battery manufacturer uses Azure IoT Central to monitor HVAC and compressor usage, cutting energy costs by 15%.

The ROI of Azure-Powered Smart Factories

For Detroit manufacturers, moving to Azure isn’t just a tech upgrade—it’s a business transformation. Key benefits include:

- Reduced Downtime: Predictive maintenance and real-time monitoring can save millions annually.

- Lower Operational Costs: Hybrid cloud and energy optimizations reduce infrastructure and energy expenses.

- Improved Product Quality: AI-driven inspection reduces recalls and improves customer trust.

- Faster Time-to-Market: Connected supply chains enable faster design-to-production cycles.

- Scalability: Azure grows with the business, from one plant to global operations.

Overcoming the Skills Gap in Detroit

One barrier Detroit manufacturers often cite is the skills gap how to upskill workers to manage cloud-based systems. Microsoft and partners like Info Services offer training programs, managed services, and local expertise to bridge this gap. Solutions like low-code Power Apps also allow non-developers to build factory apps quickly.

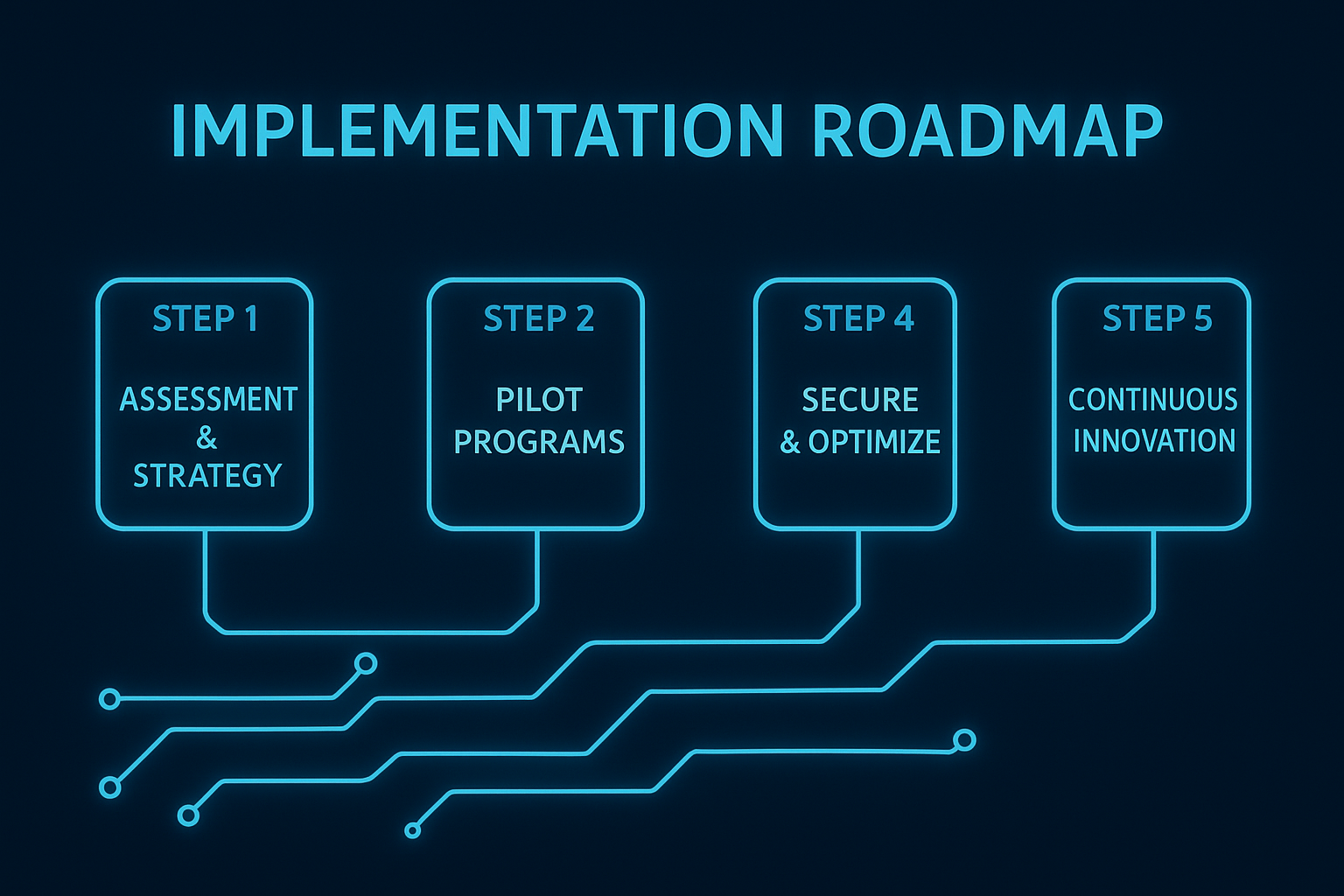

Implementation Roadmap: How to Start with Azure

For manufacturers in Detroit, the path to Industry 4.0 with Azure can be phased:

- Assessment & Strategy

- Identify critical pain points (downtime, quality issues, supply chain delays).

- Align Azure solutions to business outcomes.

- Pilot Programs

- Deploy IoT sensors on a limited set of machines.

- Run predictive maintenance as a proof of concept.

- Scale Across Plants

- Expand IoT and analytics across multiple facilities.

- Integrate Azure Digital Twins for entire production lines.

- Secure & Optimize

- Layer in Azure Sentinel for cybersecurity.

- Use Azure Cost Management to optimize cloud spend.

- Continuous Innovation

- Train teams, integrate AI, and adopt edge computing for real-time use cases.

Local Relevance: Why This Matters for Detroit

Detroit is uniquely positioned to lead Industry 4.0 because of its:

- Automotive dominance: OEMs and suppliers can’t afford downtime or poor quality.

- Skilled manufacturing base: Workers can be upskilled with cloud-based tools.

- Innovation culture: From startups to established auto giants, Detroit has always been a hub for industrial reinvention.

By embracing Azure, Detroit can secure its role as a global manufacturing powerhouse in the 21st century.

Conclusion: The Road Ahead

Industry 4.0 isn’t a distant vision it’s happening now. For Detroit manufacturers, the question isn’t if to modernize but how fast. Microsoft Azure provides the digital backbone for smart factories, enabling predictive maintenance, connected supply chains, AI-driven quality, and sustainable operations.

The companies that act today will not only reduce costs and improve efficiency but will also set themselves apart as innovators in Detroit’s next industrial revolution.

Ready to explore how Azure can transform your Detroit factory into a smart factory? Our Azure specialists at Info Services help manufacturers design, implement, and optimize Industry 4.0 solutions tailored to your operations.

FAQ'S

1. What makes Microsoft Azure essential for Detroit’s smart factories?

Azure provides a secure, scalable foundation integrating IoT, AI, and analytics, enabling Detroit manufacturers to reduce downtime, optimize operations, and modernize factories for global competitiveness.

2. How does Azure support predictive maintenance in manufacturing?

Azure IoT and Machine Learning analyze real-time sensor data to forecast equipment failures, minimizing unplanned downtime, extending machine life, and helping Detroit manufacturers save millions in lost productivity.

3. Can Azure improve supply chain visibility for Detroit automakers?

Yes. Azure Synapse Analytics and Data Lake connect supplier, logistics, and demand data, giving automakers real-time insights to anticipate shortages, reduce bottlenecks, and keep assembly lines running efficiently.

4. How does Azure help Detroit manufacturers achieve sustainability goals?

Azure IoT and AI track energy consumption, optimize resource usage, and reduce waste, enabling manufacturers to cut costs while meeting sustainability and carbon reduction commitments.

5. What steps should Detroit manufacturers take to start with Azure?

Begin with a digital assessment, run small-scale IoT pilots, expand across plants, secure operations with Azure Sentinel, and continuously innovate using AI and edge solutions for lasting transformation.