Combining Azure AI and Robotics in Smart Factories: The Future Is Now

Azure AI is empowering robots to transform production from end-to-end.

In today's era of rapid digital transformation, the manufacturing industry is embracing a powerful new alliance: Azure AI and robotics. This union is redefining innovative factory capabilities by automating tasks, enabling predictive insights, and optimizing every stage of the production process. What was once science fiction is now an operational reality. In 2025, smart factories powered by Azure and intelligent robotics are driving unprecedented levels of efficiency, precision, and agility.

This blog examines how Azure AI and robotics are revolutionizing modern manufacturing, showcasing real-world applications, business benefits, and strategies for leveraging this technology to achieve Industry 4.0 success.

1. Why Azure AI and Robotics Are Transforming Smart Manufacturing

The integration of Azure AI with robotics is no longer experimental—it's central to modern manufacturing strategies. Here's why this convergence matters:

- Cognitive Capabilities: Azure AI empowers robots to understand, analyze, and make informed decisions, transforming them from programmed machines into intelligent collaborators.

- Edge and Cloud Synergy: With Azure IoT Edge, factories can deploy AI models directly on robotic hardware while syncing data to the cloud for deeper analytics.

- Real-Time Data Insights: Azure Machine Learning and Cognitive Services process vast datasets to uncover performance trends, predict maintenance needs, and suggest improvements.

- Flexible Adaptation: Intelligent robots powered by Azure can adapt in real-time, adjusting processes based on variables like temperature, product type, or material changes.

By combining robotics with Azure's robust AI infrastructure, manufacturers gain autonomous, self-optimizing systems that reduce errors, lower costs, and enhance productivity.

2. Visual Quality Inspection Using Azure Cognitive Services

Traditional quality control often involves manual checks or rigid rule-based systems that can miss subtle defects. With Azure AI and robotic vision, factories are now implementing intelligent visual inspection systems.

How It Works:

- Robots equipped with high-resolution cameras scan components on the assembly line.

- Azure Cognitive Services (notably Custom Vision) analyzes visual data in real-time.

- Defective items are flagged or automatically removed by robotic arms.

Real-World Example:

An electronics manufacturer in South Korea implemented Azure-powered visual inspection on robotic arms. The result? A 30% increase in inspection speed and a 60% drop in defect-related customer complaints.

3. Autonomous Work Cells: Smarter Operations on the Shop Floor

Robotic work cells—zones where robots perform specific tasks like welding or assembly—are getting a significant upgrade with Azure AI.

Traditional Challenge:

Manual programming and fixed processes make it challenging to adapt work cells to product changes or anomalies.

Azure-Powered Solution:

- Machine learning models analyze force, torque, and motion data.

- Robots dynamically adjust based on part variability or tool wear.

- Azure AI Copilot can guide operators during changes or troubleshooting.

Automotive Application:

A major German automaker used Azure ML to power robotic welding cells. The result? A 25% reduction in rework and a 15% boost in throughput.

4. Predictive Maintenance for Robotic Equipment

Unplanned downtime is a significant cost factor in manufacturing. Azure AI enables predictive maintenance by analyzing telemetry from robotic systems.

Implementation Steps:

- Data from sensors (vibration, torque, temperature) is collected via Azure IoT Hub.

- Azure Machine Learning models identify patterns that precede failures.

- Maintenance alerts are triggered before breakdowns occur.

Case Study:

A packaging facility in the U.S. reduced robotic downtime by 50% and saved over $1 million annually after deploying an Azure-based predictive maintenance solution.

5. Real-Time Factory Optimization with Azure Digital Twins

A key part of Industry 4.0 is the digital twin—a virtual replica of your physical factory that updates in real-time.

Azure Digital Twins Capabilities:

- Model physical assets like robotic cells, AGVs, and environmental systems.

- Simulate production scenarios and optimize task routing to enhance efficiency.

- Integrate with Azure Maps and IoT Hub for spatial analytics and visualization.

Smart Factory Scenario:

When a robotic work cell overheats, the digital twin detects the anomaly, simulates load balancing, and reroutes tasks to other cells—all without human intervention.

6. Enhancing Human-Robot Collaboration with Azure AI Copilots

The future of smart factories isn’t just about automation—it’s about collaboration. Azure AI Copilots enable seamless human interaction with robotic systems.

Use Cases:

- Ask natural-language questions, such as, "Why is cell 3 underperforming today?"

- Get real-time answers and suggestions via dashboards powered by Azure OpenAI.

- Enable faster decision-making and reduce training time for operators.

Benefits:

- Reduced shift handover times.

- Empowered frontline workers.

- Better alignment between operations and engineering teams.

7. Sustainable Manufacturing with Intelligent Automation

Azure AI and robotics are also advancing sustainability goals:

- Energy Optimization: AI algorithms reduce energy usage by dynamically adjusting machine loads.

- Waste Reduction: Vision systems minimize scrap by detecting defects earlier.

- Resource Efficiency: Predictive maintenance reduces the need for spare parts and extends the life of equipment.

Smart factories are becoming greener by design, thanks to the intelligence infused through Azure's cloud and edge services.

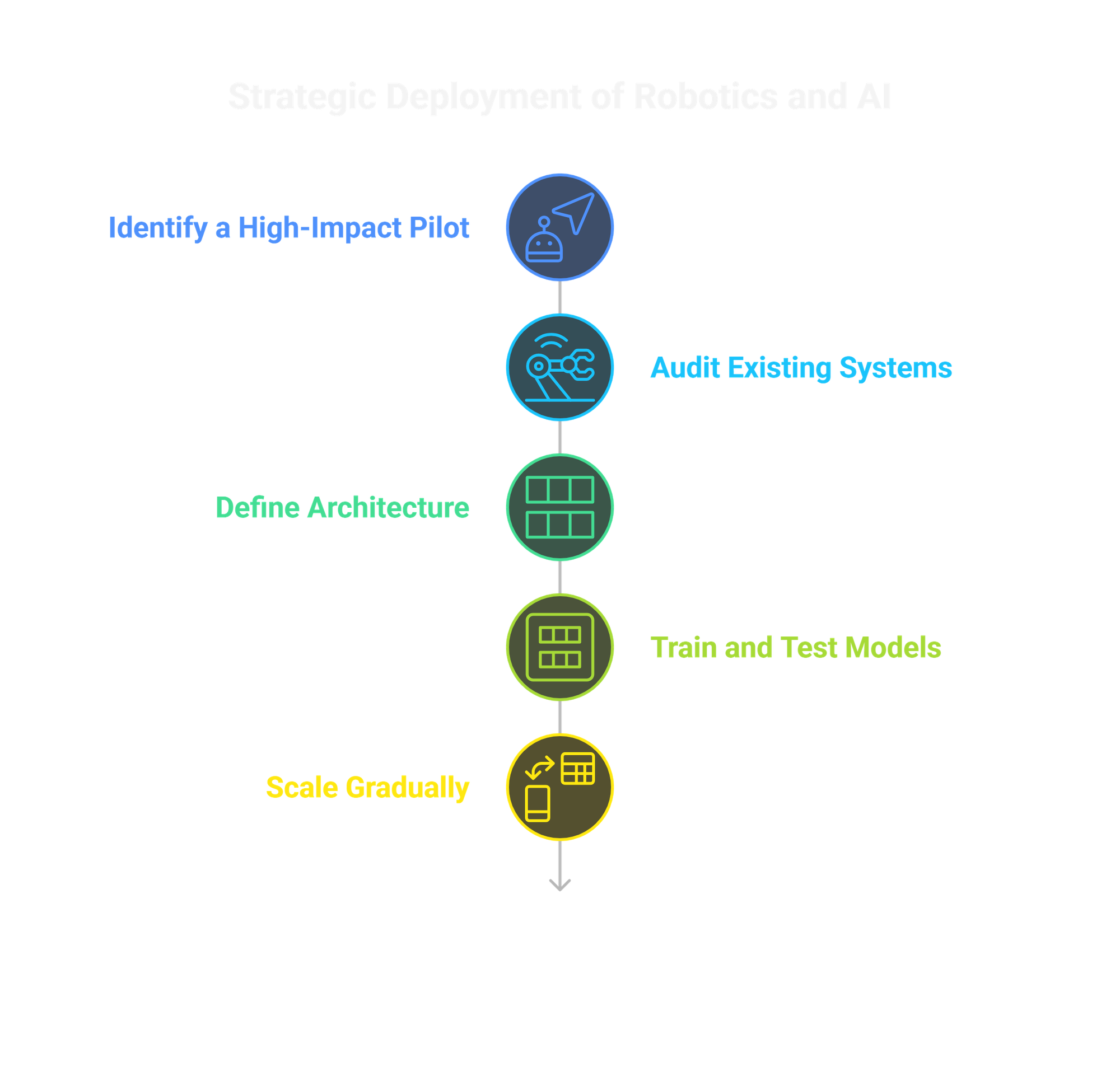

8. Deployment Strategy: How to Get Started

Step 1: Identify a High-Impact Pilot

Choose a use case that is repetitive, high-volume, and measurable (e.g., quality inspection or predictive maintenance).

Step 2: Audit Existing Systems

Map out current robotics infrastructure, data sources, and connectivity protocols.

Step 3: Define Architecture

- Use Azure IoT Edge for on-premises AI execution.

- Integrate Azure ML and Cognitive Services.

- Build digital twins for live factory modeling.

Step 4: Train and Test Models

- Use historical data to train machine learning models.

- Deploy on pilot cells and refine with operator feedback.

Step 5: Scale Gradually

- Move from one cell to an entire line.

- Standardize data collection and model deployment processes.

- Establish KPIs for ongoing optimization.

9. Key Metrics to Track Success

Track these with Azure Monitor and Power BI:

- Production Throughput: Are you producing more with the same resources?

- Defect Rate: Are AI systems improving quality control?

- Downtime: How much time is saved through predictive maintenance?

- Energy Usage: Are intelligent systems optimizing consumption?

- Employee Engagement: Are Workers Benefiting from AI Copilots?

By regularly tracking these metrics, manufacturers can fine-tune their smart factory operations.

Why Detroit Matters in the Future of Smart Manufacturing

Detroit, long regarded as the heartbeat of American manufacturing, is rapidly evolving into a hub for intelligent automation and AI-powered production. With its strong automotive legacy and skilled industrial workforce, the city is embracing Azure AI and robotics to revitalize legacy systems and enable Industry 4.0 innovations. As smart factories emerge across the Midwest, Detroit stands out for its strategic investments in AI-driven predictive maintenance, robotic welding automation, and digital twin deployments. By leveraging Microsoft Azure’s powerful cloud and edge capabilities, Detroit-based manufacturers are unlocking new levels of efficiency, quality, and sustainability—reaffirming the city’s status as a global manufacturing leader.

Final Thoughts

The combination of Azure AI and robotics is not just enhancing smart factories—it’s redefining them. With real-time insights, autonomous adjustments, and seamless human-machine collaboration, this technology is setting new benchmarks in productivity and innovation.

Manufacturers ready to embrace this future can gain a competitive edge today. Azure's ecosystem provides the flexibility, scalability, and intelligence needed to power next-generation factories that are adaptive, efficient, and sustainable.

FAQ'S

Q: How are Azure AI and robotics improving quality control for manufacturers in Houston?

A: In Houston's dynamic manufacturing sector, Azure Cognitive Services enable intelligent visual inspection with robotic arms. This technology, crucial for industries from chemicals to aerospace, analyzes products in real-time, instantly identifying defects. This precision significantly reduces rework and boosts efficiency for Houston-based facilities, minimizing costly production errors.

Q: What predictive maintenance benefits do Detroit's automotive manufacturers gain from Azure AI and robotics?

A: Detroit's automotive industry significantly benefits from Azure AI for predictive maintenance. By analyzing sensor data from robotic equipment, Azure Machine Learning predicts potential failures before they occur. This proactive approach minimizes costly downtime on assembly lines, as evidenced by a German automaker's 25% rework reduction, ensuring continuous operation vital for Michigan's manufacturing heartland.

Q: How does Azure AI and robotics optimize autonomous work cells for Chicago-area factories?

A: For Chicago's diverse manufacturing base, Azure AI enhances robotic work cells with adaptive intelligence. Machine learning models allow robots to dynamically adjust tasks, improving efficiency and flexibility for processes like assembly and welding. This real-time adaptability means Chicago factories can respond faster to production changes, optimizing throughput and reducing manual interventions.

Q: Can Azure Digital Twins optimize factory operations for manufacturing hubs like Houston, Detroit, and Chicago?

A: Absolutely. Azure Digital Twins create virtual replicas of factories in Houston, Detroit, and Chicago, providing real-time oversight. This enables manufacturers to simulate production scenarios, optimize task routing, and respond instantly to anomalies, enhancing operational efficiency without human intervention. It's a game-changer for complex production environments in these major US hubs.

Q: What makes Azure AI and robotics a sustainable choice for US manufacturing, particularly in cities like Chicago?

A: Azure AI and robotics contribute to sustainable manufacturing across US hubs, including Chicago. AI algorithms optimize energy usage by dynamically adjusting machine loads, while vision systems reduce waste by detecting defects earlier. Predictive maintenance extends equipment life, minimizing resource consumption. This intelligent automation helps Chicago's factories achieve greener, more efficient operations.