The Future of Manufacturing: Efficiency and Growth Through Applied AI

AI reshaping manufacturing growth

Introduction: Manufacturing at a Turning Point

Manufacturing has always defined progress. Steam power revolutionized production in the 18th century, assembly lines reshaped efficiency in the 20th century, and industrial robotics gave rise to automation in the late 20th century. Now, the sector faces its next inflection point in artificial intelligence (AI).

But unlike earlier transformations that emphasized speed or scale, this wave centers on intelligence. AI is not simply about replacing tasks with machines; it’s about making factories smarter, more resilient, and capable of adapting to disruptions in real-time.

Manufacturers today operate in one of the most volatile environments in history. Supply chain breakdowns, global inflation, workforce shortages, and rising sustainability demands create a perfect storm. Against this backdrop, Google Cloud recently launched its “Applied AI for Modern Manufacturers” series, aimed at exploring how manufacturers can harness AI to not just weather challenges but build long-term competitive advantage.

The question is no longer whether AI can improve manufacturing—it’s whether leaders will deploy it strategically enough to stay ahead.

The Three Core Challenges Facing Manufacturers

1. Operational Volatility

Globalized supply chains, once celebrated for efficiency, are increasingly fragile. Geopolitical tensions, shipping delays, and raw material shortages can cause cascading bottlenecks. Traditional forecasting models—often built on spreadsheets and historical averages simply cannot handle today’s level of volatility.

For manufacturers in Detroit’s automotive hubs or in global heavy industry, the inability to predict or react quickly translates directly into lost production time and millions in revenue leakage.

2. Workforce Gaps

The labor challenge is twofold: an aging workforce nearing retirement and a shortage of younger talent entering the industry. Recruiting engineers, technicians, and skilled operators is increasingly difficult. Training new workers is equally challenging when processes involve highly complex machinery.

Without scalable solutions, manufacturers risk losing both institutional knowledge and the agility needed to onboard replacements quickly.

3. Growth vs. Sustainability

The push for growth collides with an equally urgent mandate: environmental responsibility. Manufacturers face pressure from regulators, investors, and customers to reduce carbon emissions, cut waste, and prove alignment with ESG commitments.

Balancing production efficiency with sustainable practices requires real-time intelligence, something traditional enterprise systems weren’t built to provide.

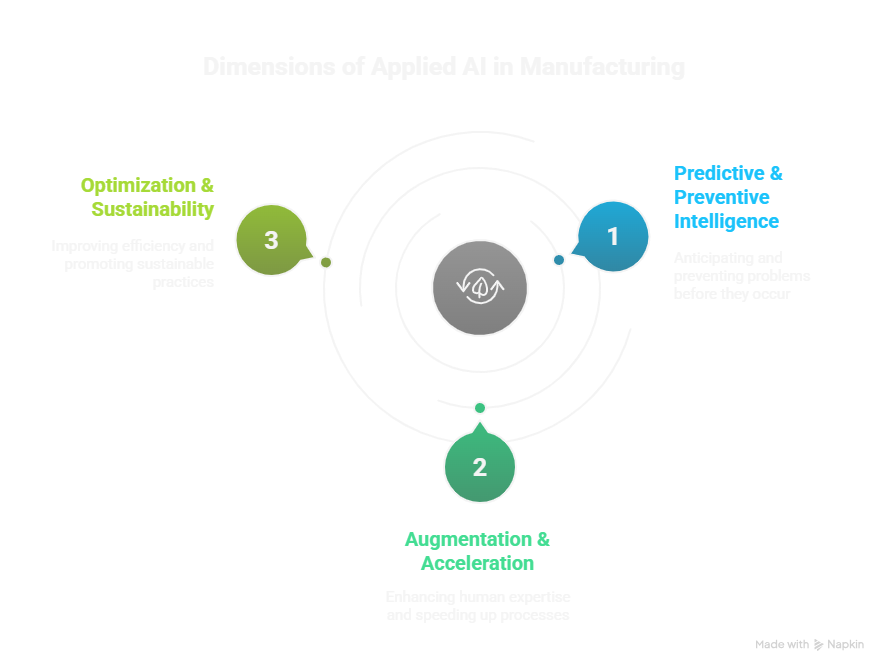

How Applied AI Responds to Modern Challenges

Applied AI goes beyond automation. Where automation streamlines repetitive tasks, AI brings foresight, adaptability, and optimization across every level of the production cycle. Its impact can be grouped into three dimensions:

1. Predictive & Preventive Intelligence

Instead of reacting to problems after they occur, AI helps manufacturers anticipate and prevent them.

- Demand Forecasting: Machine learning models account for seasonality, market trends, and external variables—like tariffs, weather, or geopolitical shifts—to create highly accurate predictions.

- Predictive Maintenance: Sensors embedded in machines stream data to AI models that predict breakdowns before they happen, minimizing downtime.

- Anomaly Detection: Real-time monitoring of production parameters allows AI to flag abnormalities before they escalate into defects or delays.

2. Augmentation & Acceleration

AI augments human expertise, enabling workers to do more with less.

- Digital Twins: Virtual replicas of equipment and production lines allow engineers to test process changes without physical risk.

- AI-Powered Training: Combining virtual reality with adaptive AI modules accelerates onboarding and reskilling for new employees.

- Assisted Decision-Making: AI platforms surface insights from terabytes of operational data, helping executives choose optimal production strategies.

3. Optimization & Sustainability

Optimization is where AI turns incremental improvements into large-scale transformations.

- Energy Management: AI models continuously adjust HVAC, lighting, and machinery usage to lower utility costs.

- Carbon Tracking: AI integrates IoT sensor data to measure emissions per unit of output, providing visibility into sustainability performance.

- Circular Economy Enablement: By analyzing material flows, AI identifies opportunities to reuse components, minimize scrap, and reduce waste.

Use Cases: Applied AI in Action

Automotive Manufacturing

Detroit’s automakers are leading the charge in AI adoption. With just-in-time supply chains stretched to their limits, AI has become a lifeline.

One automotive manufacturer turned to Google Cloud’s AI forecasting tools to predict semiconductor demand six months in advance. The result: a 15% reduction in downtime, ensuring production stayed on schedule during a global chip shortage.

Pharmaceuticals & Life Sciences

Pharma and life sciences companies face strict compliance and traceability requirements. AI enhances quality control, anomaly detection, and equipment maintenance.

For example, one pharma manufacturer deployed AI-driven quality inspections on production batches. The initiative reduced rejected runs by 20%, saving millions annually while ensuring regulatory compliance.

Heavy Machinery & Industrial Equipment

In industries where a single piece of equipment can cost millions, downtime is catastrophic. Applied AI-driven predictive maintenance minimizes these risks.

A global equipment maker installed AI sensors on CNC machines. By predicting wear and failure patterns, they cut unplanned downtime by 40%, dramatically improving both asset utilization and customer trust.

Consumer Goods & Electronics

For fast-moving consumer goods, time-to-market often determines success. AI accelerates prototyping, streamlines logistics, and improves demand planning.

A consumer electronics firm leveraged AI to forecast holiday shopping trends with unprecedented accuracy. Aligning production with demand prevented overstocking and ensured shelves stayed full during peak season.

Food & Beverage

AI helps maintain freshness, safety, and compliance in one of the most tightly regulated industries.

A beverage company adopted computer vision systems to identify labeling defects in real time. This avoided recalls, protected brand reputation, and ensured compliance with food safety standards.

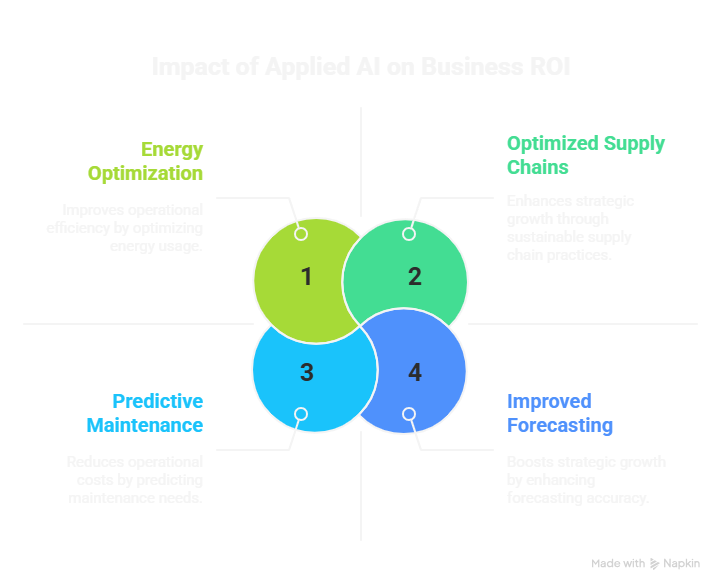

Measuring ROI: Executive-Level Impact

When executives ask about ROI, Applied AI provides measurable results across four key areas:

- Efficiency Gains: Predictive maintenance and energy optimization reduce operational costs by 15–20%.

- Revenue Growth. Improved forecasting means better product availability and fewer lost sales.

- Risk Reductio:n AI-powered quality assurance prevents costly recalls and compliance penalties.

- Resilience & Sustainability Reduced waste, lower emissions, and optimized supply chains contribute to long-term agility and ESG compliance.

The bottom line: AI investments pay off not only in cost avoidance but also in enabling new growth opportunities.

Implementation Challenges and How to Overcome Them

While the potential is vast, manufacturers often face barriers on the road to AI adoption.

Challenge 1: Data Silos

Manufacturers operate with fragmented IT and OT (operational technology) systems, making data integration difficult.

- Solution: Cloud platforms like Google Cloud BigQuery unify structured and unstructured data, providing a single source of truth.

Challenge 2: Change Management

Adopting AI requires cultural change and new skill sets.

- Solution: Begin with pilot projects such as predictive maintenance or defect detection. Demonstrating early wins builds momentum for broader adoption.

Challenge 3: ROI Justification

Executives need hard numbers before approving large-scale investments.

- Solution: Target quick-win use cases with fast payback periods, then scale successes across the enterprise.

Looking Ahead: The Future of AI in Manufacturing

The next leap in manufacturing will be driven by agentic AI systems—autonomous agents capable of negotiating with suppliers, scheduling production, and adapting workflows without human intervention.

Paired with advanced infrastructure like Google Cloud’s TPU v7 (Ironwood), these systems will process billions of data points in real time, enabling factories to function as dynamic, self-optimizing ecosystems.

By the end of the decade, we can expect:

- AI-Driven Autonomous Factories: Supply, production, and distribution fully synchronized without manual oversight.

- An AI-Augmented Workforce: Humans collaborating seamlessly with AI copilots, supported by digital twins and real-time simulations.

- Hyper-Personalized Products: AI enabling mass customization while reducing waste and enhancing customer satisfaction.

Conclusion: Turning Pain Points into Competitive Advantage

Manufacturing leaders stand at a crossroads. The traditional playbook—manual forecasting, siloed data systems, and reactive problem-solving—no longer works in an era defined by disruption. Applied AI provides the tools to rewrite this playbook.

By adopting predictive intelligence, augmenting their workforce, and embedding sustainability into operations, manufacturers transform pain points into competitive advantages.

For executives, the decision isn’t whether AI will reshape the industry—it already has. The real decision is whether to lead the transformation or risk being left behind.

Learn more about how our Google Cloud services help manufacturers modernize their infrastructure and deploy AI at scale.

FAQs

1. How is applied AI different from automation?

Automation speeds tasks, while AI predicts, adapts, and optimizes processes in real time.

2. What’s the best first step to adopt AI?

Start small with quick-win use cases like predictive maintenance or demand forecasting.

3. How does AI support sustainability goals?

AI tracks emissions, cuts energy use, and finds ways to reduce waste.

4. What infrastructure is needed for AI in manufacturing?

A modern cloud foundation, like Google Cloud, to unify data and scale AI securely.